group assignment:

Computer-Controlled Machining

group project

Safety

hence when we got in touch with it we adopted all the necessary safety measures to use it properly.

This means that a minimun of two people were required to be present for every moment that the machine was operating, and both were required to wear safety glasses and headphones.

Beyond that, even before testing anything, we made sure that the emergency button was working properly.

Once verified that it did, we proceeded to set up every step with the necessary precautions,

meaning to turn of all the necessary switch when we had to operate on the machine itself.

hence when we got in touch with it we adopted all the necessary safety measures to use it properly.

This means that a minimun of two people were required to be present for every moment that the machine was operating, and both were required to wear safety glasses and headphones.

Beyond that, even before testing anything, we made sure that the emergency button was working properly.

Once verified that it did, we proceeded to set up every step with the necessary precautions,

meaning to turn of all the necessary switch when we had to operate on the machine itself.

the runout,alignment,speed, feeds and toolpath was done through cutting and observing the the output as shown below

Shopbot CNC

We using the the Shopbot cutter

runout, alignment, speeds, feeds, toolpaths

make (design+mill+assemble) something big

i decided to go make something that i will benefit with since i finished school and i am moving alone for the first time i decided to go with bed design

There were other options of making shelves and sits but i couldnot manage in 5 days

i decided to cut with solidworks to design the appearence of the bed

The design i decide to cut looks as follows

which the final product was anticipated to be like

I decided to first familiarize with the shopbot cutting software which was part of the group assignment before continuing to cutting

Final cut bed looked like the following

i went a head first and looked for wood to use, mostly i decided to use the remains of woods found in the stre to minimize the cost

I decided to assemble the cut parts using by making the groves as shown

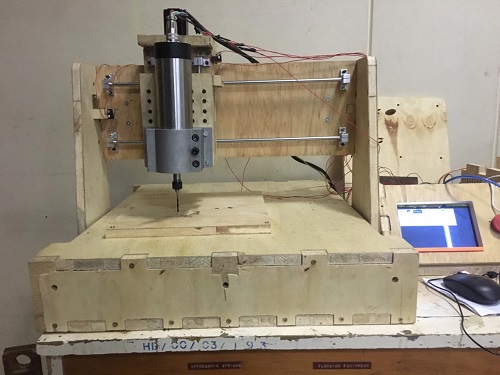

I went ahead and used the same skills learned here to cut and assemble cnc machine for machining week

you can get the files here

Design File Back